Blog / News -

Sustainable Manufacturing, Intentional Design, and Outstanding Quality

CASABLANCA BRIDAL WAS ESTABLISHED IN 1997 AND HAS SINCE BECOME ONE OF THE FASTEST GROWING, WELL-KNOWN MANUFACTURERS OF BRIDAL GOWNS IN THE INDUSTRY.

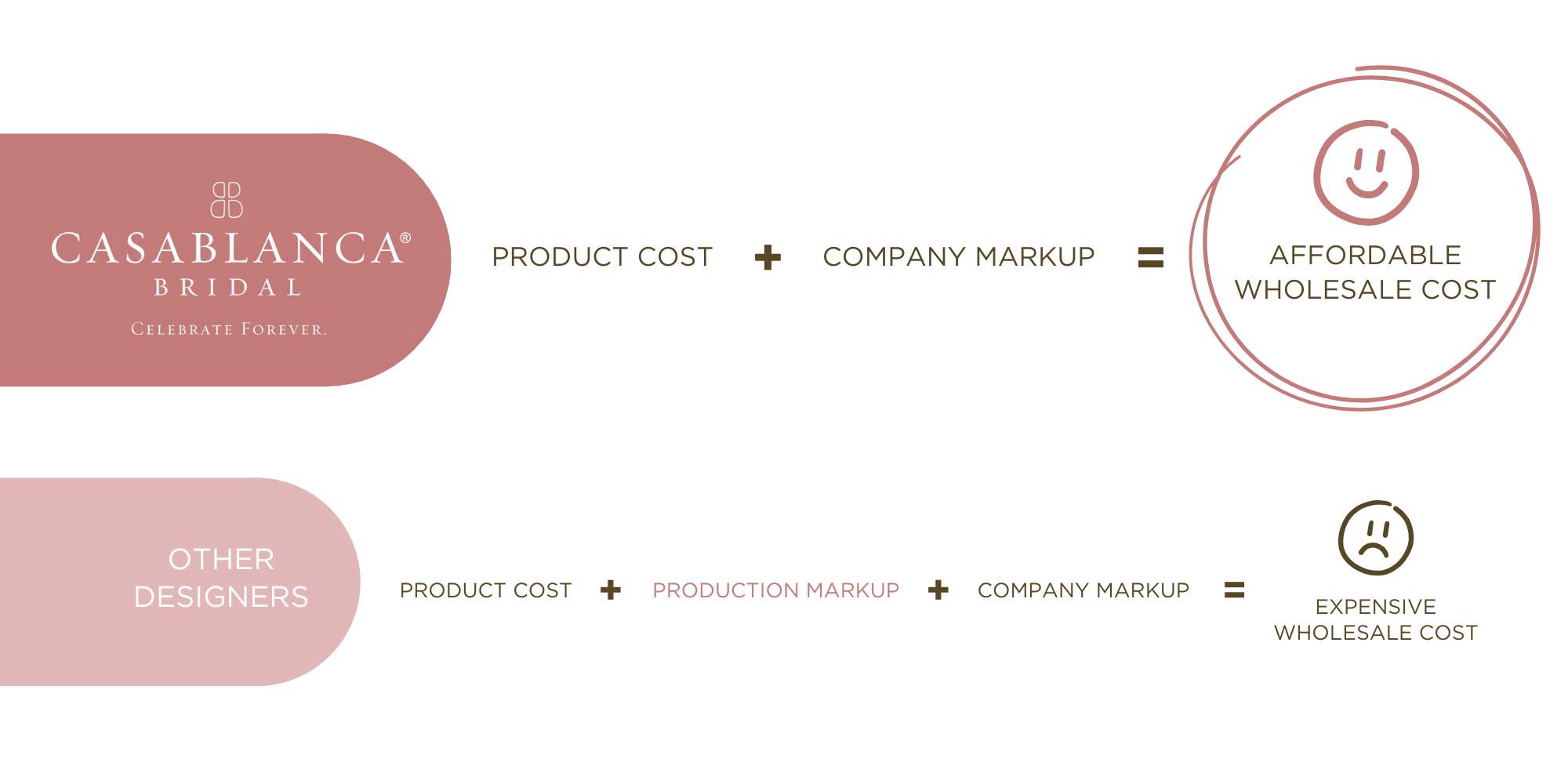

Our state-of-the-art manufacturing facility allows us to provide all of our brands for an affordable price without sacrificing quality. Unlike most brands who externally subcontract their production, Casablanca Bridal prides itself on manufacturing all our gowns and accessories internally. Major brands in our industry markup their products way higher than the actual cost.

We do things differently.

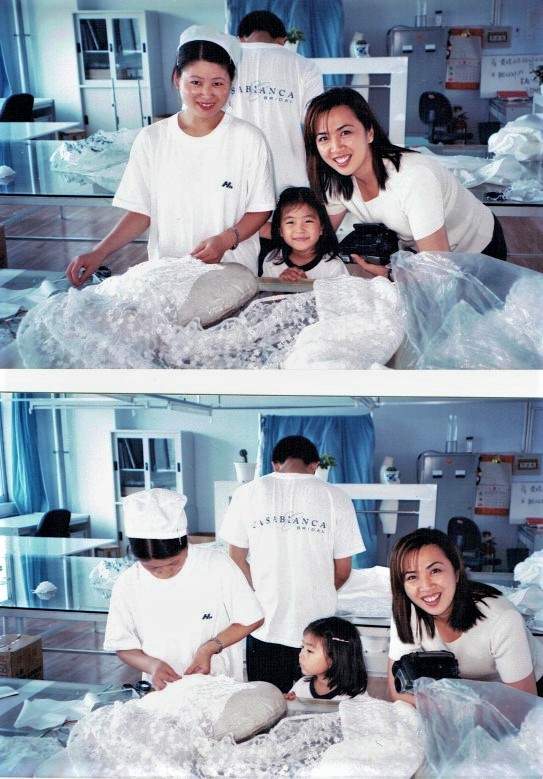

In the mid-90's, our cofounders Kevin and Gloria Lu flew to China to secure the best manufacturing facility. Unfortunately, after touring several sites, they were extremely disappointed with the working conditions; their feet were pitch black and covered in dirt after each tour. The Lu’s had no idea how they’d be able to create beautiful clean gowns under these conditions....

They decided to take matters into their own hands and opened their first “factory” in a small office-like space with just six sewing machines and a handful of factory workers!

(Co-Founder Gloria Lu (right) with daughter and Creative Director Crystal Lu (middle)

(Co-Founder Gloria Lu (right) with daughter and Creative Director Crystal Lu (middle)

at one of Casablanca’s original factories)

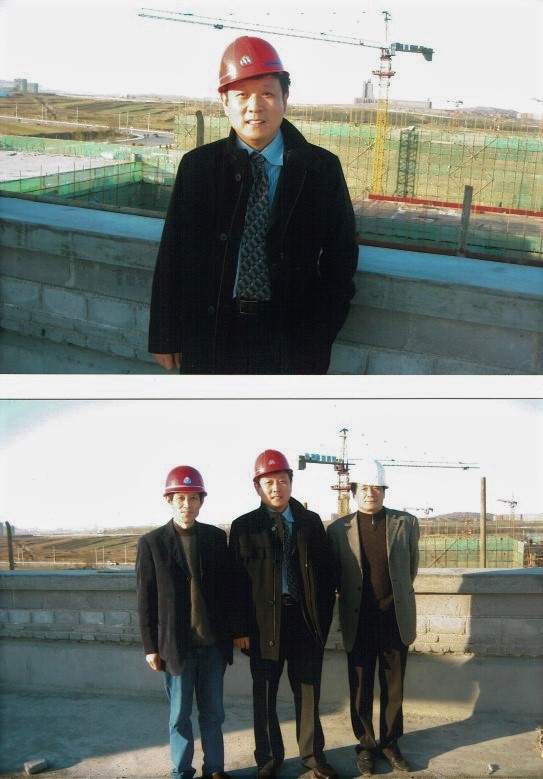

As the brand quickly took off, the Lu's transitioned through multiple buildings until they eventually decided to create their own campus which is where our beautiful collections are made now.

(Map Overview of Casablanca Bridal’s Manufacturing Facility, CEO Kevin Lu at construction site)

(Map Overview of Casablanca Bridal’s Manufacturing Facility, CEO Kevin Lu at construction site)

Having our own facility allows us to prioritize the well-being and safety of our employees. As a family business, it was also important to build the facility near Kevin’s parents who lived in the northern part of China, making it easy to combine work trips with family visits.

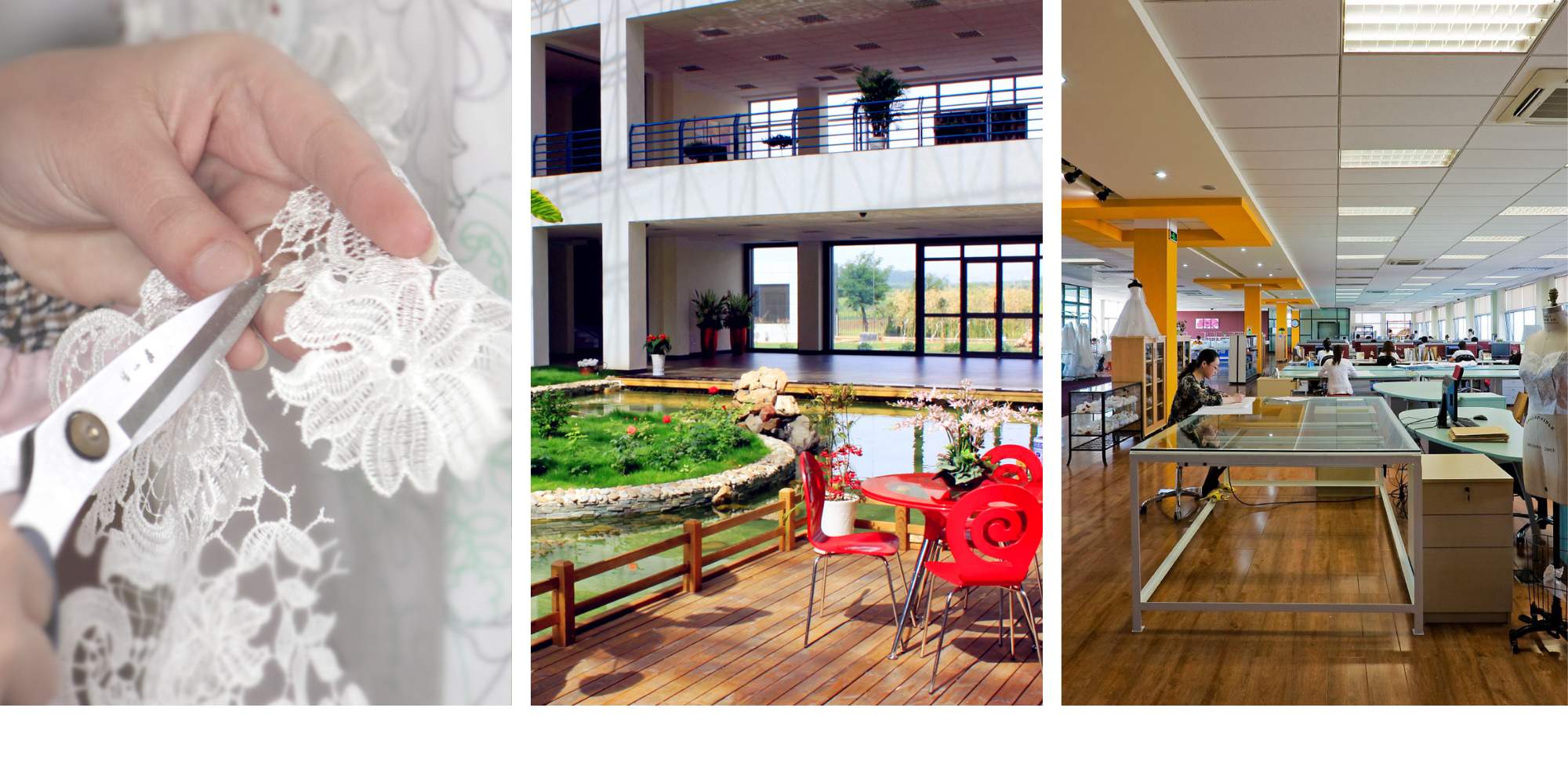

Many details went into the construction of our manufacturing facility including: 1. Heated Floors 2. Indoor Garden & Koi Pond 3. High Glass Ceilings with Natural Light 4. Connected Dormitory 5. Comfortable Working Spaces 6. Chef Prepared Meals 7. Leisure Activities (i.e. Movie Theater, Ping Pong Room, Basketball, and More) 8. BONUS: Close Proximity to Beach Offering Scenic Ocean Views

Over the course of many years our factory has been honored to employee over 1,000 people. The governor of our province has given our factory honorable mentions for greatly benefiting the community and local economy.

Our unique manufacturing approach also gives us an amazing opportunity to lessen our carbon footprint and utilize our fabrics and laces across the spread of all our brands, ultimately reducing our microfiber & fabric waste.

Here's how we do it:

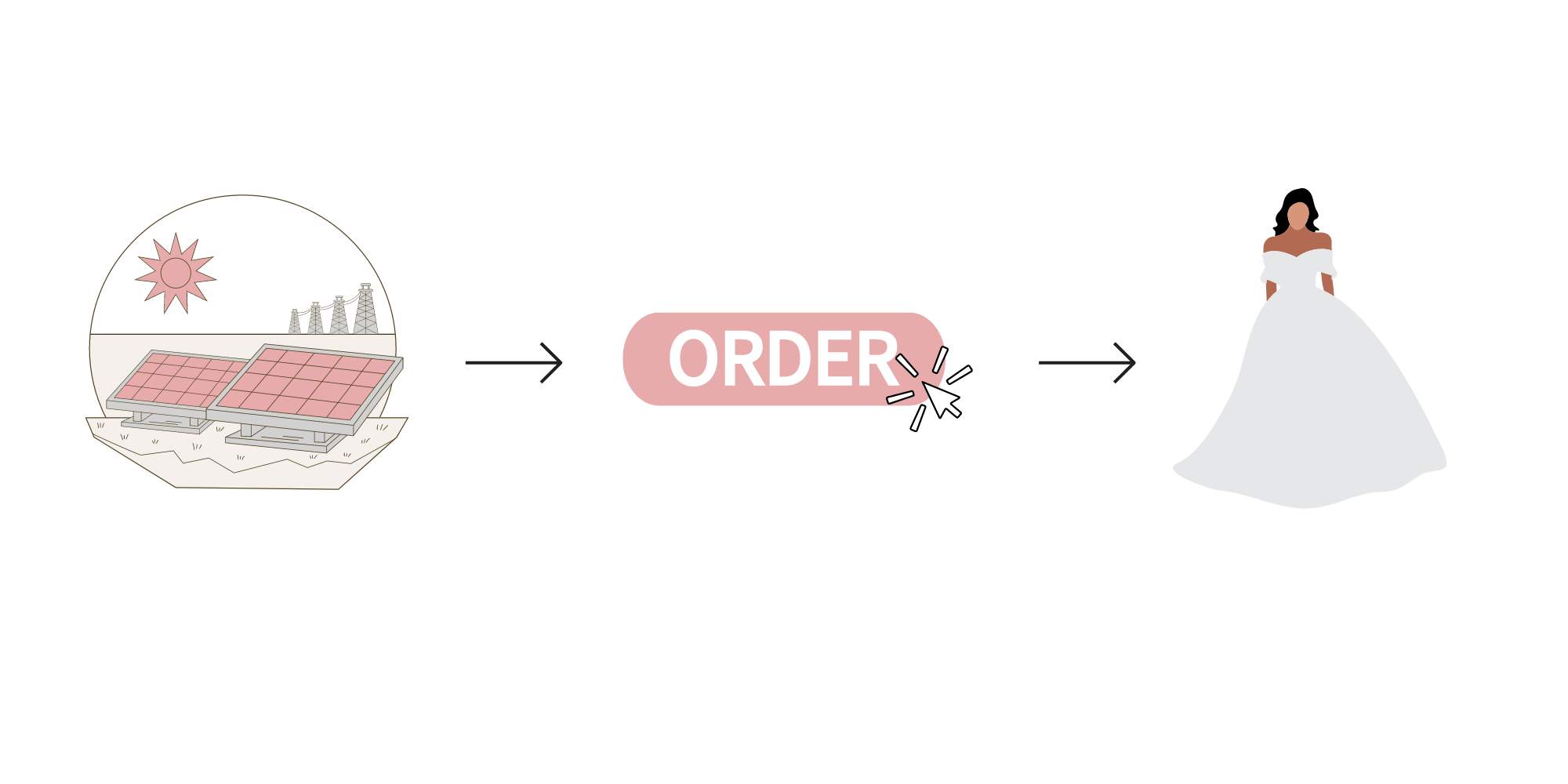

- RENEWABLE ENERGY SOURCE: All the water in our manufacturing facility is heated by solar panels, greatly reducing the use of energy for our staff.

- MADE-TO-ORDER: All our gowns are made-to-order meaning production will only begin once we receive an order, rather than unnecessarily mass-producing in excess.

- NEVER DISCONTINUE: Many Retailers are often forced to abruptly dispose of mass inventory for discontinued styles, thus increasing waste & levels of surplus stock ending up in landfills.

We are proud to offer 25+ years of dress styles and we love that we can provide brides with the ability to customize each gown. We want our brides to feel valued and cared for, so all our dresses are made-to-order. This allows us to take a bride’s custom measurements to ensure the best fit for their dream dress. Not only does this give us the ability to treat every bride with the utmost care, but it also allows us to be a sustainable manufacturer.